Electrical insulation comprises materials such as plastics, polymers, and fluoropolymers that prevent unintended current flow and safeguard components. It functions by withstanding electrical stress, resisting heat, and shielding circuits from interference. Common materials include polyethylene, PVC, and epoxy resin, selected based on their durability and the surrounding environment.

Failures in insulation can occur due to factors such as ageing, environmental conditions, or electrical overload. Recent innovations are now concentrating on smarter, eco-friendly, and sensor-enabled insulation solutions, providing more reliable and sustainable options as technology evolves.

As electrical systems continue to advance, the importance of effective insulation cannot be overstated, ensuring safety and efficiency in a wide range of applications.

Types of Electrical Insulation Materials

There are several main types of electrical insulation materials, each suited to different applications based on their unique properties.

Plastic insulation materials, particularly polymers, are widely used due to their excellent dielectric properties and flexibility. For example, polyethylene is commonly employed in power cables because of its high resistance and durability, while PVC serves as a cost-effective option for electrical wiring. Plastic materials, especially polymers, are chosen for their ease of processing and wide range of application options. Polypropylene sheets are utilised to protect circuits and devices by enclosing them, and fluoropolymers, such as Teflon, offer strong mechanical strength and chemical resistance, making them suitable for high-temperature or harsh environments.

Rubber materials, including natural rubber and EPDM, provide low-temperature flexibility and resistance to water and abrasion.

Ceramic and glass insulators are capable of withstanding high voltages, which makes them ideal for outdoor power lines.

These materials play vital roles in ensuring that electrical systems remain safe and reliable.

Principles of Electrical Insulation

Understanding the principles of electrical insulation is essential for ensuring the safe and efficient operation of electrical systems. Insulation prevents unintended electrical current flow between conductors, thereby enhancing safety and overall system performance.

Key concepts include dielectric strength, which indicates how effectively an insulator can withstand electrical stress without failing. Thermal management is also critical, as insulation must handle heat to protect equipment from damage.

The selection of materials is influenced by properties such as durability, thermal stability, and resistance to environmental factors. Additionally, proper installation and regular testing are vital to maintaining insulation effectiveness and avoiding potential hazards.

By adhering to these principles, electrical systems can become safer, more reliable, and longer-lasting.

- Prevents unintended current flow between conductors

- Resists electrical stress to avoid breakdown

- Manages heat to protect equipment

- Requires proper installation and testing

- Ensures safety and system efficiency

Applications of Insulation in Electrical Systems

Electrical insulation plays a crucial role in various systems by preventing unwanted electrical current flow and protecting equipment from damage.

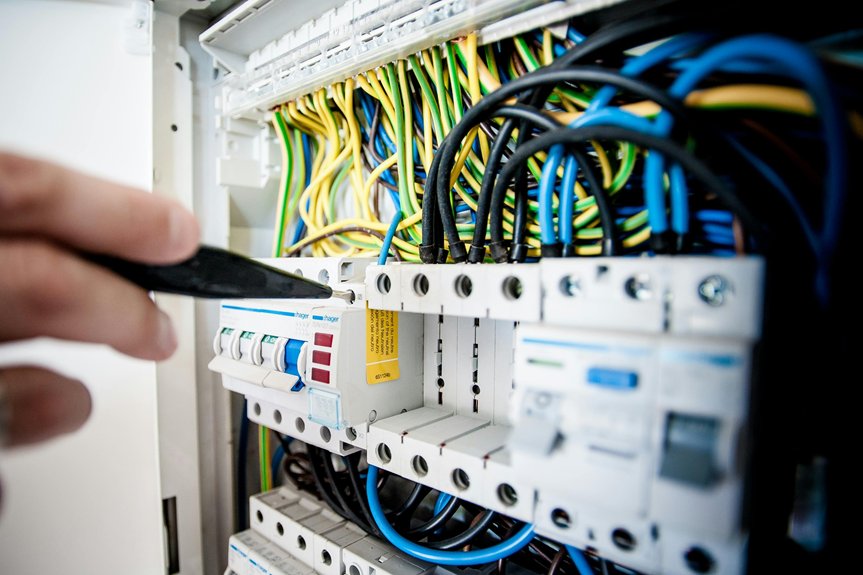

In industrial electrical systems, insulation serves as a barrier that isolates conductive parts, thereby reducing the risks of short circuits and leakage. It also enhances energy efficiency by minimising power loss and heat generation during current flow, while shielding sensitive components from electromagnetic interference and electrical discharges. Proper insulation materials are selected based on specific environmental and operational requirements.

For electrical machines and motors, specialised materials such as epoxy resin and mica-based compounds are employed to withstand challenging conditions like high temperatures and humidity, thereby extending their operational lifespan.

In power transmission, insulation is vital for overhead line insulators made from durable, high-performance materials, ensuring safety and preventing flashovers.

Common Insulation Failures and Their Causes

Common insulation failures frequently arise from a blend of environmental, mechanical, and electrical factors that gradually weaken the material.

These complications can lead to insulation cracking, deterioration, or even complete breakdown.

Electrical stresses, such as overvoltages, can inflict physical damage like cracking or delamination.

Mechanical stresses, including high winds and temperature fluctuations, may also result in cracks that undermine the integrity of the insulation.

Additionally, the natural ageing of insulation materials makes them more susceptible to failure.

Environmental contaminants, such as dirt and salt, can cause surface discharges, further diminishing the insulation’s effectiveness.

Exposure to ultraviolet light and chemicals can also accelerate degradation. UV radiation and chemical exposure can break down the chemical bonds within insulation materials, compromising their durability over time.

Key factors contributing to insulation failures include:

- Electrical stress resulting from overvoltages

- Mechanical forces due to adverse weather or movement

- The natural ageing process of insulation materials

- Exposure to extreme temperature variations

- The accumulation of dirt or salt on surfaces

Innovations and Future Trends in Electrical Insulation

Recent advances in electrical insulation are centred around the development of smarter, more adaptable materials that respond to varying environmental and electrical conditions.

Innovative substances such as phase-change compounds have the ability to absorb or release heat, contributing to stable temperatures and enhanced safety for equipment.

Electro-responsive polymers can modify their dielectric properties in response to changes in voltage, leading to improved performance. Furthermore, integrated sensors facilitate real-time monitoring of temperature, humidity, and electrical stress, enabling proactive maintenance before issues arise.

Self-healing materials are being explored, which can mend microcracks, thereby extending the lifespan of insulation and minimising downtime. Researchers are also focusing on nanocomposites and advanced polymers that enhance performance in high-voltage applications.

In addition, environmentally friendly options, including hemp fibre and mycelium, are emerging as sustainable alternatives.

The development of biodegradable insulation materials further reflects the industry’s commitment to ecological sustainability, aiming to reduce waste and carbon footprint. These trends aspire to enhance the safety, reliability, and ecological friendliness of electrical systems, while fostering a sense of community through collaborative efforts to innovate and improve everyday technology.

Conclusion

Electrical insulation is essential for the safe and efficient operation of electrical systems. Various materials serve distinct purposes, from preventing electrical shorts to withstanding challenging environmental conditions. A thorough understanding of the principles of insulation, as well as common causes of failure, can significantly enhance the longevity and safety of electrical components.

Innovations in advanced materials and techniques are paving the way for improved insulation performance in the future. Overall, proper insulation ensures that electrical devices operate reliably while minimising risks. This makes insulation a critical facet of electrical engineering that continues to evolve alongside technological advancements.