Sound insulation foam is designed to reduce noise by absorbing or blocking sound waves effectively. Common shapes include wedge and pyramid designs, with wedge panels specifically targeting mid to high frequencies, while pyramid configurations assist in diffusing sound.

Open-cell foam is particularly proficient at sound absorption, and opting for thicker panels can enhance performance even further. These types of foams are widely utilised in recording studios, industrial environments, and various building projects.

The choice of material plays a significant role in both the effectiveness and safety of the sound insulation foam. To understand how different foam options can cater to your specific acoustic requirements, further exploration is encouraged.

Types of Sound Insulation Foam

There are several common types of sound insulation foam, each designed to meet specific needs in controlling noise and enhancing sound quality.

Wedge foam features ridges that effectively trap sound waves, making it ideal for reducing mid to high-frequency sounds. This type of foam is popular in recording studios. The design of wedge foam allows it to absorb sound more efficiently due to its uneven surface.

Pyramid foam has a textured, pyramid-shaped surface that diffuses sound waves, improving clarity while also adding aesthetic appeal, making it suitable for control rooms and home cinemas.

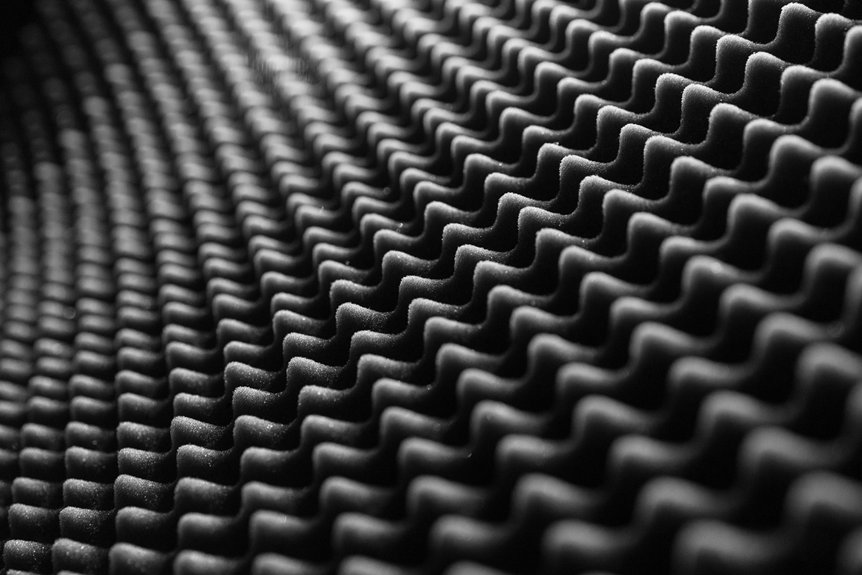

Egg crate foam, characterised by its rounded peaks, is lightweight and cost-effective, primarily serving to reduce high-frequency noise in larger spaces.

Bass traps are thicker foam panels that absorb low-frequency bass sounds. They’re typically positioned in the corners of rooms to optimise sound quality.

Smooth foam panels are flat and less absorbent, but they’re useful as a base layer beneath textured foams.

These various foam types contribute to creating better sound environments across a range of different spaces.

Performance Characteristics and Benefits

Sound insulation foam’s performance is significantly influenced by its specific characteristics, which directly affect its ability to reduce noise and enhance sound quality.

Open cell foam is particularly effective at absorbing mid- and high-frequency sounds due to its porous, breathable structure, making spaces quieter and clearer. Because open cell foam has an interconnected network of cells, it allows sound waves to penetrate and dissipate within the material.

Thicker foam panels, especially those exceeding a certain thickness, tend to have higher Noise Reduction Coefficients, which indicates improved sound absorption.

Conversely, closed cell foam, although less adept at sound absorption, excels at blocking noise and resisting moisture due to its dense and rigid construction.

The density and thickness of the foam are crucial factors impacting its effectiveness, with softer, thicker open cell foam providing superior sound control.

Furthermore, its lightweight and easy-to-install nature makes it a practical choice for creating a more comfortable and acoustically connected environment.

Suitable Applications for Different Foams

Different types of foam are suited to various applications depending on their unique physical and acoustic properties.

In industrial settings, open-cell polyurethane foam lines machinery enclosures, effectively absorbing noise generated by motors and pumps. Foams with heat and moisture resistance are particularly useful in engine compartments and power plants due to their durability in demanding environments.

Polyester-based foams are widely utilised for sound management within medical devices and business equipment, ensuring a quieter operation.

In the transportation sector, melamine and polyurethane foams are essential for insulating aircraft and trains, significantly reducing noise from engines and airflow. Furthermore, foam linings in ductwork and fuselage panels help minimise sound transmission, contributing to a more peaceful travel experience.

In building construction, open-cell foams are commonly employed in walls and ceilings to control reverberation, while foam sheets placed beneath floors effectively reduce impact noise.

Additionally, foam gaskets and seals are crucial for blocking sound leaks around doors and panels, enhancing overall quietness and comfort in various environments. Foam’s versatility allows it to be customized for specific soundproofing needs across multiple industries.

Material Choices and Their Impact

The selection of foam material is vital in determining its overall acoustic performance. Open-cell foam, characterised by interconnected pores, allows for airflow, making it softer and more effective at absorbing mid to high-frequency sounds. Open-cell foam’s porosity enhances its ability to trap sound waves, making it particularly effective in reducing echo and reverberation. In contrast, closed-cell foam features sealed cells, which confer increased density and moisture resistance; however, it’s less effective at sound absorption, primarily focusing on blocking transmission. Thickness and density are also significant factors; thicker foam tends to absorb lower frequencies, while the density influences how effectively sound is dampened. Open-cell foam is often favoured for its sound absorption capabilities, particularly in environments where optimal acoustics are essential. Material choice also impacts durability and safety. Certain foams are treated to be fire-retardant, while others may retain moisture, posing a risk for mould growth. Thus, selecting the appropriate foam involves a careful balance of performance, environmental considerations, and fire safety requirements.

Conclusion

Choosing the right sound insulation foam is essential for addressing the unique acoustic requirements of various environments. Different types of foam provide diverse levels of soundproofing, durability, and ease of installation.

By understanding the performance features and appropriate applications of each type, you can make informed choices. The materials available also play a crucial role in determining effectiveness and overall cost.

Selecting the right foam can lead to a significant enhancement in acoustic quality while remaining mindful of budget and spatial limitations. Thus, investing in sound insulation is a practical and valuable decision for improving sound management in your space.