Eurothane is a high-performance rigid foam insulation crafted from polyisocyanurate (PIR), renowned for its low thermal conductivity and exceptional fire resistance. It is available in various types, including Eurothane GP, which is ideal for ground floors, and Eurothane Eurodeck, specifically designed for flat roofs, catering to diverse building requirements.

This insulation material is lightweight yet durable, providing outstanding moisture resistance, making it a favoured choice in the construction industry. Proper storage and handling are crucial for ensuring optimal performance, while adherence to relevant standards guarantees safety.

In the following sections, we will explore its applications and offer installation tips to maximise its benefits in your projects.

Overview of Eurothane Products and Material Composition

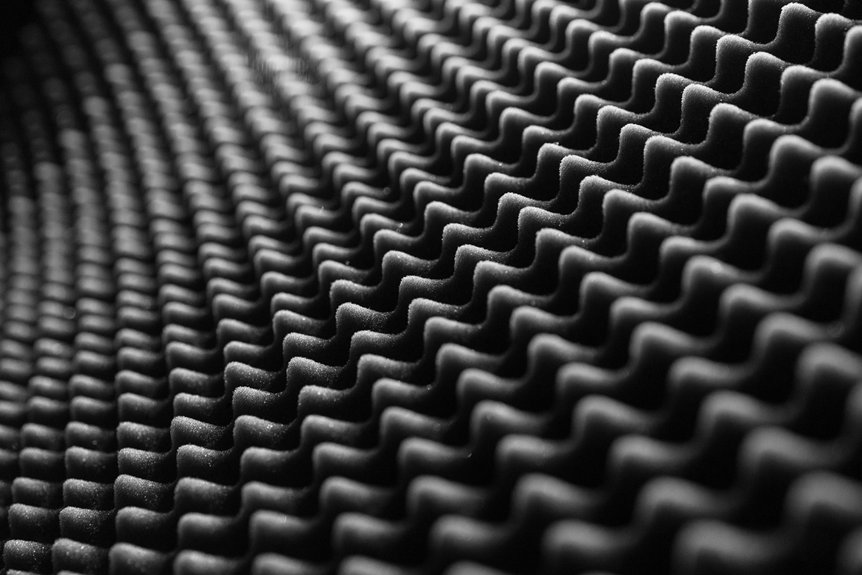

Eurothane products are predominantly composed of a core material known as rigid polyisocyanurate (PIR) foam, renowned for its exceptional thermal performance and stability. This insulation material boasts a low thermal conductivity, effectively minimising heat transfer across various applications. PIR foam also offers excellent fire resistance compared to other insulation materials. The insulation boards are available in a range of thicknesses to meet diverse insulation requirements. To enhance their functionality, the surfaces of these boards are often coated with a low emissivity aluminium foil, which improves vapour resistance. Despite their lightweight nature, Eurothane boards provide impressive mechanical strength, featuring a density that ensures durability and resilience. These boards are designed to be rot-proof and capable of withstanding moisture, ensuring longevity and reliability as a choice for building insulation. With their robust properties, Eurothane products are an excellent solution for maintaining energy efficiency in various construction projects.

Variants and Specific Applications of Eurothane Insulation

Various variants of Eurothane insulation are designed to meet specific building needs and regulatory standards in the UK.

Eurothane GP is particularly suitable for ground floors, offering high compressive strength and outstanding thermal efficiency with a low thermal conductivity. Its lightweight nature makes it easy to cut, and it’s compatible with underfloor heating, ensuring a quick and straightforward installation process. Eurothane GP is also known for its excellent moisture resistance, which helps maintain insulation performance over time.

For pitched roofs, Eurothane GP is effective in creating warm roof constructions, which help to minimise condensation risks and enhance usable space by transforming roof voids into habitable areas. The insulation is available in an array of thicknesses to accommodate different U-value requirements.

Eurothane Eurodeck is specially designed for flat roofs, featuring aluminium foil facings that provide certified durability. This variant effectively addresses concerns related to thermal bridging and wind uplift.

These Eurothane insulation options offer versatile solutions for various building applications, ensuring both insulation efficiency and compliance with UK building regulations.

Storage, Handling, and Certification Standards

Proper storage and handling of Eurothane insulation are essential to maintaining its performance and ensuring safety during installation. The insulation boards should be stored indoors or under cover, as their packaging isn’t suitable for outdoor use.

It’s important to keep them dry, place them off the ground, and cover them with weatherproof sheets to prevent moisture absorption. Avoiding direct sunlight is crucial to prevent UV damage. Any boards that become wet must be discarded and not used.

When handling Eurothane insulation, care is necessary to avoid puncturing the aluminium foil facing. It’s advisable to use protective gear such as masks and goggles, particularly when cutting or generating dust. The boards should also be stored horizontally to prevent warping.

The quality of Eurothane insulation is assured by compliance with standards such as EN 13165 and ISO certifications. Additionally, environmental and safety standards stress the importance of proper disposal and the need to store materials away from heat and flammable substances.

Following these guidelines will help ensure that Eurothane insulation performs effectively while promoting a safe working environment.

Conclusion

Eurothane products provide a reliable choice for insulation requirements, featuring a diverse range of options tailored for various applications. Their materials are meticulously formulated to comply with industry standards, ensuring safety during storage and handling. By gaining a clear understanding of the different variants and standards, users can select the most suitable Eurothane insulation for their projects.

Overall, Eurothane’s consistent quality and commitment to certification standards render it a dependable solution within the construction and insulation sectors.