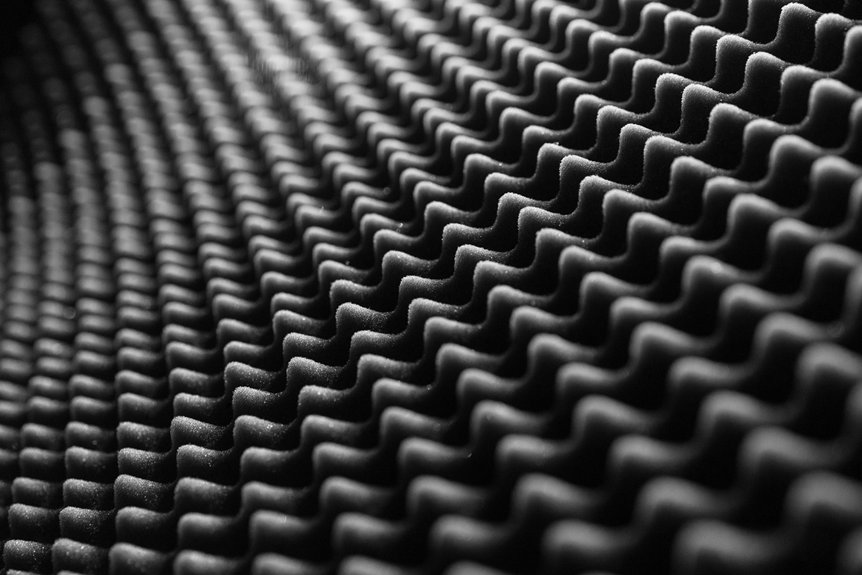

Expanding foam insulation is available in two primary types: open-cell and closed-cell. Open-cell foam is softer and particularly effective for sound absorption, while closed-cell foam is denser, offering superior moisture control and acting as a robust vapour barrier.

Upon application, expanding foam expands to fill gaps and cavities, ensuring a snug fit. The rate of expansion and density are crucial factors that influence both insulation performance and longevity. When used correctly, expanding foam can significantly enhance energy efficiency, but it is important to observe safety precautions due to the chemicals and volatile organic compounds (VOCs) involved.

In this guide, we will explore how to select and apply expanding foam insulation for optimal results, helping you make informed choices for your insulation needs.

Types and Variations of Expanding Foam Insulation

Expanding foam insulation is available in a variety of types and formulations, each tailored for specific applications and performance requirements. The two primary types are open-cell and closed-cell foam, which differ significantly in their cellular structure and characteristics. Open-cell foam is softer and has excellent sound absorption qualities. It requires a greater thickness to achieve an airtight seal, making it suitable for certain applications where noise reduction is a priority. In contrast, closed-cell foam is denser and serves as an effective vapour barrier. This type is ideal for situations where moisture control is crucial, as it can provide a solid seal with less material. The delivery systems for these foams include low-pressure kits, which are perfect for smaller projects such as attics and crawl spaces. For larger jobs, like new builds, high-pressure rigs are more appropriate, providing the necessary coverage and efficiency. These foams also differ in density and thermal resistance, commonly referred to as R-value, which impacts their insulation effectiveness and durability. Each type presents unique advantages, facilitating the selection of the right product for your home’s specific insulation needs. The cellular structure of expanding foam significantly influences its insulation properties and application methods. With the right choice, expanding foam insulation can significantly enhance energy efficiency and comfort within your living spaces.

How Expansion and Density Affect Insulation Performance

The manner in which foam expands and its resultant density plays a crucial role in determining its insulation performance. Increased expansion can lead to the formation of larger cells, which may facilitate heat transfer, consequently diminishing the efficiency of insulation.

In contrast, foam with a higher density provides enhanced thermal resistance. This is because it reduces gas exchange within the cells and improves longevity. Additionally, it contributes to greater mechanical strength and durability.

- Controlled expansion optimises insulation performance by preserving cell integrity.

- Lower-density foam may be more effective at filling gaps but can lack strength.

- Higher-density foam delivers superior long-term thermal stability.

- Achieving the right balance between expansion and density is essential for optimal insulation and structural support.

Striking the appropriate balance ensures that the foam maintains its performance over time, helps in reducing energy costs, and provides a lasting, reliable seal. Density impacts the longevity of foam insulation, as denser materials tend to resist deformation and degradation caused by environmental factors.

Application Areas and Practical Tips for Using Expanding Foam

Choosing the appropriate application areas and practical tips can greatly enhance the effectiveness of expanding foam. It is particularly suitable for sealing small to medium gaps around windows, doors, pipes, and wall edges, creating airtight barriers that help reduce draughts. The foam conforms to irregular shapes, effectively filling cavities in various locations, including exterior holes, thus preventing the entry of pests and moisture. Additionally, it stabilises pipes by filling surrounding gaps, minimising movement.

However, caution is necessary; expanding foam should not be used around electrical boxes or near heat sources, as it may pose hazards. For insulation purposes, foam is highly effective in attics, walls, and basements, particularly around rim joists and HVAC ductwork. Correct application ensures energy efficiency, soundproofing, and moisture sealing.

| Application Area | Practical Tip |

|---|---|

| Gaps around doors and windows | Use foam specifically designed for those gaps to avoid damage. |

| Insulating walls | Verify the R-value to ensure compliance with building regulations. |

| Sealant for pipes | Fill gaps around pipes to minimise rattling and movement. |

Safety, Environmental Concerns, and Best Practices

Using expanding foam safely requires an understanding of the health risks and environmental concerns associated with its use. Isocyanates present in spray foam can lead to respiratory issues such as asthma, wheezing, and coughing, as well as skin and eye irritation. Prolonged exposure may result in heightened sensitivity, making individuals more susceptible to allergies and asthma from various irritants.

Furthermore, the chemicals found in foam can emit volatile organic compounds (VOCs), contributing to indoor air pollution. There are also fire hazards due to flammable gases contained in the cans, and toxic gases may be released during combustion.

To ensure safe usage, it’s essential to adhere to proper safety measures:

- Always wear appropriate protective gear, including respirators, gloves, and goggles.

- Ensure the area is well-ventilated to promote adequate airflow.

- Carefully follow the manufacturer’s instructions and safety data sheets.

- Provide training for workers on correct handling procedures and emergency protocols.

Proper ventilation is crucial during application to minimize VOC buildup and protect indoor air quality.

Conclusion

Expanding foam insulation provides versatile solutions for enhancing energy efficiency across a range of applications. Understanding the various types, their expansion properties, and correct usage can optimise effectiveness while ensuring safety.

It is crucial to adhere to best practices, consider environmental impacts, and handle the material with care. When chosen and applied properly, expanding foam can deliver durable and effective insulation that contributes to reducing energy costs and improving overall building performance.

A solid understanding of expanding foam insulation ensures safe, efficient, and environmentally responsible insulation practices.