Sound deadening insulation employs materials such as mineral wool, fibreglass, or cotton to absorb or block noise in buildings. The effectiveness of these materials depends on factors like their density, thickness, and the location of application—be it walls, floors, or ceilings. There are also eco-friendly alternatives available, including cork and recycled textiles.

Proper installation is crucial; sealing any gaps can significantly enhance the performance and longevity of the insulation.

To uncover effective solutions tailored to your specific acoustic needs, continue exploring how these materials and techniques work in harmony to elevate your acoustic comfort.

Types of Sound Deadening Materials and Their Acoustic Properties

There are several types of sound deadening materials, each with unique acoustic properties suited for different applications.

Mineral wool insulation is naturally fire-resistant and water-repellent, making it suitable for various environments. It boasts high sound absorption capabilities, often achieving excellent ratings, and can dampen a wide range of frequencies, making it ideal for walls and ceilings.

Fibreglass insulation is lightweight and easy to install, offering effective sound absorption across many frequencies. It’s a popular choice among builders and renovators for its practicality.

Cotton and cellulose soundproofing are eco-friendly and affordable options that excel at absorbing high-frequency sounds. However, they may not provide the same level of water and fire resistance as other materials.

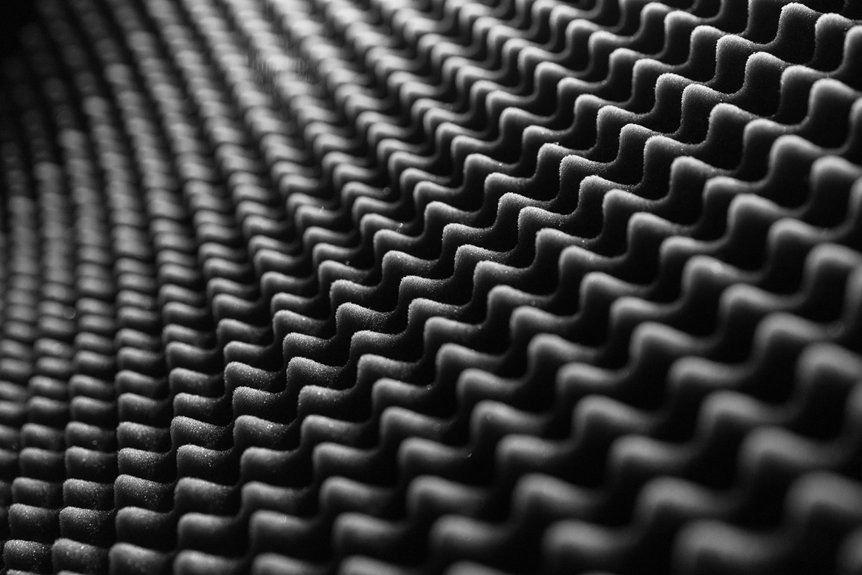

Foam-based materials, such as spray foam and polyurethane, are versatile and often employed in various applications. Nevertheless, it’s important to note that these materials can be flammable, which may influence safety considerations.

Mass-loaded solutions, like vinyl and rubber mats, provide dense sound blocking, particularly effective for airborne noise. These materials are often used in spaces requiring enhanced acoustic performance, and their high density enhances soundproofing efficiency.

Applications and Best Use Cases for Soundproof Insulation

Soundproof insulation is extensively utilised across various environments to manage noise levels and enhance comfort.

In residential properties, insulation for exterior walls effectively blocks outdoor sounds such as traffic and neighbourhood noise, contributing to a more tranquil living space. Internal walls can be equipped with sound-absorbing materials like cellulose or spray foam, which help to prevent sound transmission between different rooms. Properly installed insulation can significantly improve a home’s overall soundproofing performance. Attics insulated with cellulose or fibreglass not only improve thermal efficiency but also diminish impact noise from weather conditions and foot traffic. Floors separating living areas can be treated with specialised materials, resulting in a significant reduction of footstep and impact noise, particularly in flats.

In commercial environments, sound insulation plays a crucial role in creating privacy within offices by minimising distractions. Theatres and recording studios often employ fibreglass panels to manage reverberation, ensuring optimal sound quality. Educational institutions and shared living spaces also greatly benefit from soundproofing, fostering a peaceful atmosphere conducive to learning and relaxation.

Installation Techniques and Practical Considerations

Proper installation techniques are essential for maximising the effectiveness of soundproofing materials.

First, surfaces must be thoroughly cleaned and free of debris, grease, or dust, particularly in vehicle applications. Use solvents if necessary and smooth out sharp edges to protect the insulation during the installation process. Cleaning the surfaces ensures proper adhesion and prevents future disturbances in soundproofing performance.

Second, insulation should completely fill cavities and be securely pressed with a roller to eliminate air gaps.

Third, when applying sound deadening mats, cut them to size and ensure full contact by pressing firmly.

Fourth, sealing seams with soundproof caulks and staggering drywall joints will help prevent sound leaks.

By following these steps, you create a stable environment where soundproofing performs best.

Proper surface preparation and careful application contribute to long-lasting, effective sound insulation that everyone can appreciate.

Environmental Impact and Safety Aspects of Soundproofing Options

Choosing soundproofing materials involves not only considering their effectiveness in blocking noise but also understanding their impact on the environment and human health.

Many eco-friendly options, such as cork, hemp, and straw, prioritise recyclability and lower carbon footprints, thus helping to reduce resource extraction and emissions. Some materials are produced through closed-loop processes, which reuse manufacturing waste to minimise landfill waste.

Materials like PET-recycled textiles and natural fibres emit fewer volatile organic compounds (VOCs), contributing to improved indoor air quality and healthier environments, particularly in schools and hospitals.

Natural products like cork or wool are biodegradable or compostable, facilitating disposal and reducing long-term waste.

While synthetic options may offer durability, their non-biodegradable nature and potential chemical emissions raise health risks and environmental concerns.

Knowing the benefits of recycled materials, such as AIM Acoustic Insulation, further demonstrates the importance of choosing products aligned with environmentally responsible practices, ensuring both safety and sustainability.

Opting for sustainable materials supports environmentally friendly building practices and promotes safer living spaces.

Factors Influencing Material Choice and Performance Effectiveness

Several factors play a vital role in determining the effectiveness of soundproofing materials, and a thorough understanding of these elements is essential for selecting the most suitable option for particular requirements.

Density and mass are significant considerations—materials with higher mass are more effective at blocking low-frequency sounds. Options such as Mass Loaded Vinyl and dense mineral wool insulation demonstrate this capability well.

Material composition and structure also influence sound absorption properties. Dense mineral wool and fiberglass offer substantial performance, whereas softer materials like cotton are particularly adept at managing high-frequency sounds.

Thickness and layering enhance sound insulation. Thicker insulation combined with different materials, such as foam paired with rubber, can significantly improve overall performance.

Installation flexibility and durability are essential factors to consider. Versatile and robust solutions like spray foam or Mass Loaded Vinyl provide long-lasting soundproofing benefits with straightforward application methods.

Conclusion

Selecting the appropriate sound deadening insulation is essential for achieving optimal acoustic performance in various settings. The choice often hinges on the specific application, environmental considerations, and the level of sound absorption required.

Different materials provide unique advantages, from effective noise reduction to eco-friendliness. It is important to understand the installation methods and safety aspects involved to ensure successful outcomes.

A well-considered selection and application of soundproofing materials can lead to a significant reduction in noise levels, enhanced privacy, and improved comfort.

Thorough evaluation guarantees that the insulation not only meets performance expectations but also adheres to safety standards, ultimately contributing to a more peaceful and pleasant environment.